Automatic Recirculation Valve Failure

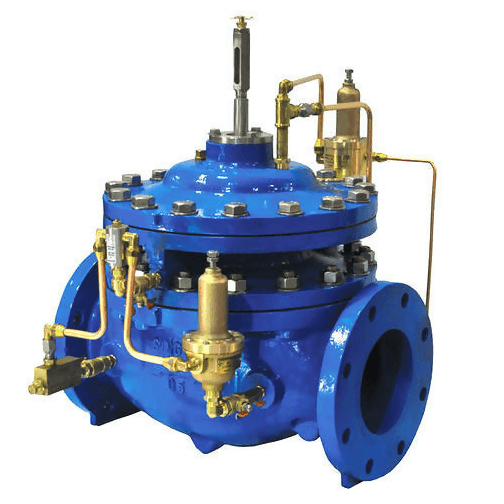

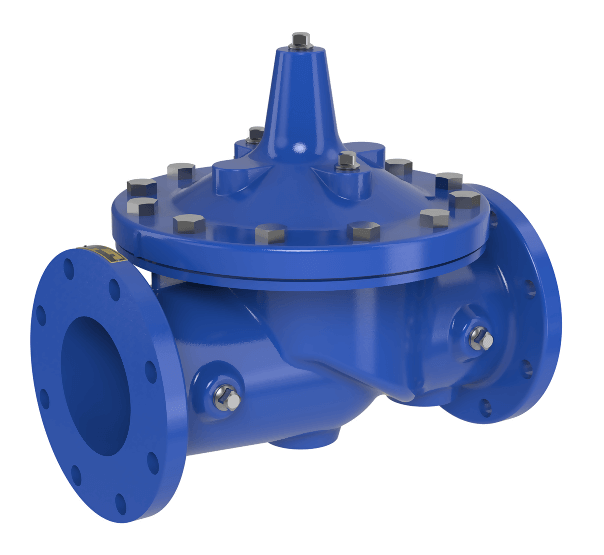

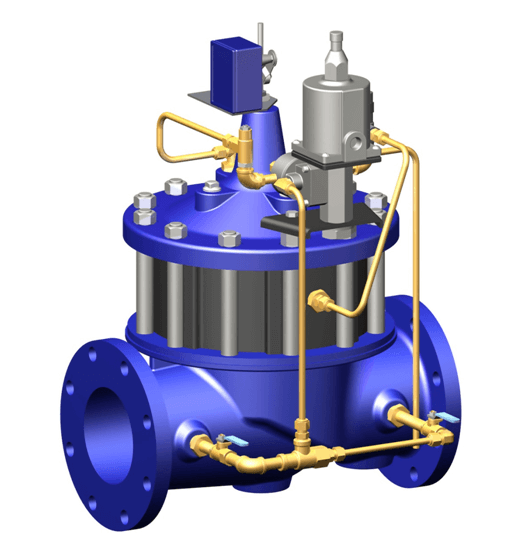

Automatic recirculation control valve works efficiently on centrifugal pumps, crude oil pump and other machines whose function is to pump fluids. To achieve the efficiency of the pipe, you have to source it from a reliable supplier. But, check on the qualities and specifications of the arc valve before purchasing to ensure it fits with your pump. However, the valve has its failures. Here are automatic recirculation valve failures you need to know and suggestions for solving them.

- Pump Surging

Automatic recirculation valve works to protect the pump. However, if there is no adequate fluid, and the automatic valve fails to control the flow of the liquid, there is a pressure build-up in the pump. When the reverse flow of fluid occurs, the speed of the pump is affected. It leads to a slowing of the impellor.

In return, there is more pressure build-up which results from thrusting bearings to wearing off sooner than expected. Therefore, you will need pump minimum flow protection, and you can purchase the valve from an online store once you confirm the supplier is reliable.

- Internal Recirculation

Internal recirculation is where the fluid flows back to the pump. It’s challenging to identify the problem because the liquid flowing again is minimum. The disadvantage of internal recirculation is its ability to form vortices, and it lowers the pressure within the pump.

It can lead to cavitation and pressure pulsations, which affects the operating process of the pump. Therefore, contact automatic recirculation valve manufacturers and order your new valve that curbs the backflow of fluids.

- Vibration Of The Rotor

Rotor vibration is as a result of low flow of fluids. It causes a disparity between the impeller and the diffuser which, when not resolved, could lead to the formation of vortices. These vortices vibrate the rotor.

The disadvantage of vibration could lead to impeller getting fatigued, which means it will stop running. It will be frustrating to replace the impeller, which is hard to come across but to prevent such scenarios, consider investing in arc valve.

Nonetheless, if you already have an automatic recirculation valve, consider uninstalling and reinstalling it. Ensure the valve is clean from rust and ask an expert whether there is a part that needs to be replaced.

- Radical Thrust

When you install the control valve wrongly, it won’t function as it’s supposed to. Also, when one of the valve parts is faulty, similarly, it won’t protect the pump. The pressure controller placed in the valve regulates the pressure of the fluid in the pumping system. However, if it fails to function the pressure in the pump grow uneven, which could lead to radical forces. High radical thrust causes vibration which can shorten seal life. Therefore, when you note the operation of the pump is different, there is an internal problem which if not rectified, could lead to complex damage.

Take Away

To identify automatic recirculation valve failure is challenging. It is therefore essential to follow a maintenance routine as the manufacturer advises. With strict maintenance routine and right installation, you can avoid almost 100% of all shortcomings attached to ARCs.