Top 10 Mistakes Attached to Laser Engraving Service

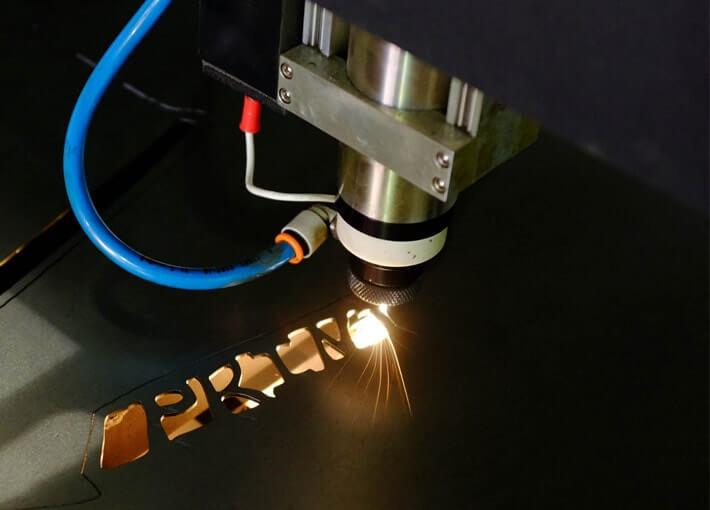

Although laser engraving service is known to be a complex art, most of its process is computerized. Graphic designers, computer technicians, and engineers are tasked to ensuring the process is successful. If you’re planning to invest in laser engraving machines; Heat Sign is one company that can give you the best machine in the market. But before you invest in this lucrative product marking business, allow me to take you through some of the common mistakes attached to laser product engraving.

- Incorrect Dates during Laser Engraving Service

By the look human eyes, you might thing engraved date is one simple thing to do. For example, jewelry dating is one common phenomenon. But one thing you need to understand is date engraving can be done in different formats. Incorrect date formatting or misspelled dates can bring forth some unintended result. You better get careful and countercheck what data you have fed into the computer before you start your laser engraver for metal jewelry or any other product.

- Incorrect Location during Laser Engraving Service

Probably, you are venturing into this engraving business, and you will be offering services to different product manufacturers. If such is your case, you need to get careful to avoid engraving your water/milk mugs, automobile, jewelry or metal product on the wrong location. If you deal with laser engraving machine for metal, after every marking service, always remember to reset your laser engraving machines to “zero.” Such will avoid staring the next laser engraving service at the center, edge or any other incorrect position.

- Misspelled Names During Laser Engraving Services

It is obvious that every product manufacturer will love his/her product to have their company name for branding and advertisement purposes. On the other hand, a gift like necklaces, chains, ring or bangles is engraved with recipients name for personal attachment and identity. Whether you are planning to use portable laser engraver, co2 laser engraver or any other, make sure you counter check name spellings to avoid mistakes.

- Assuming All Metal Surfaces Are Good for Engraving Service

Not all metal surfaces can get engraved. People think any surface can get engraved but only well prepared surfaced are eligible for laser engraving service. For example, uneven, rough or plated surfaces are not good for engraving. For rough surfaces, some surfaces will get engraved precisely while other parts will not. Such makes it impossible for customers to read the engraved details. Lastly, plated, metals might get peeled off due to too high laser light temperatures thus rendering the engraving service and the product useless.

- Buffing Makes a Surface Good For Laser Engraving Service

Metal surface buffing does not make engraving a successful; it is just but a misconception. Although re-engraving is possible on surfaces after buffing, the initial engraving must not be deep. If the first engraving was deep, then the second one will not be possible. For plated metals, desktop laser engraver or any other might not work on them. Buffing might reveal the underneath metal thus destroying your metal or jewelry.

- Laser Engraving Services Are Impossible In some Material

Another mistake that you can fall for as an engraver is thinking there are materials which cannot get engraved. If such thoughts have ever crossed your mind and you lost a potential customer, then that was a mistake. Laser engraver machinescan work on any metal. All you need to do is purchase the best laser engraver for metal, and calibrate into the correct settings.

- Not Saving The Present Condition during Laser Engraving Service

Failure to check the present condition of the material you are working on can result in poor results. For every product, you are planning to work on, ensure you test it to understand which engraving setting will produce the right results. As you look for laser engraver for metal, note that they can get calibrated to a different setting. You need to test which speed, line thickness, and laser intensity work best with the product at hand before embarking on mass engraving. Understand the nature of your product will help you choose the right engraving setting combination for quality work.

- Inconsistent Laser Engraving Service

As you go about your engraving endeavor, you need to ensure your laser engraver machines are working at a consistency setting. If the laser intensity happens to be too deep, then the metal, glass or any other material you are working on might break, get fractured or destroy that product. If you are working on some glass, makes sure the laser resolution is 300 DPI or less. Lastly, ensure the depth to which your laser beam goes is uniform to avoid the inconsistency that makes your laser engraving service look unprofessional.

- Slow Laser Engraving Service

Slow performance of your laser engraver machine can be termed as your mistake. Often, when this machine appears to be slow, lack of routine maintenance can be the cause. You need to check the optics because these are the parts that suffer most if routine maintenance is not done in time. When acrylic residues accumulate, the engraving process slows down. Clean your optics and the performance of your laser engraving machines will resume normality.

- Failure to Get White Frosty During Laser Engraving Service

In events your laser engraving service fails to produce a frosty white result, it is probable you might have made a mistake in acrylic selection. Understand there are different acrylic types. Mostly, extruded and cast acrylics are the most used types. You need to use the right acrylic precision for you laser engraver for metal, jewelry, wood and fabric products. But, between cast and extruded acrylic types; the cast is the better one although more expensive. Take your time and choose the best one that serves you right.

- Conclusion

Machines are bowed to error and wrong operation. The only thing to ensure you get the right result after every process is to avoid mistakes to the best of your knowledge. For laser engraving service, you need to be careful enough to avoid a common mistake that can jeopardize your good and well-planned engraving service delivery.