Basic Knowledge About Injection Molding And Its Uses

Injection molding is a viable scientific process used in plastic injection. Over the years, it has changed the industry that manufactures plastic in different forms. Not only is it efficient, but economical too. It’s also revolutionized the manufacturing processes of different products in the sector. Usually, injection molding is used to scale production. Immediately the initial cost of production has been paid; the price begins to drop. Here are the additional facts about plastic injection molding and its impact on plastic wall thickness.

- Plastic Molding Can Be Used To Create A Thick Plastic Wall

When it comes to designing plastic, you need to understand the basics of having a thick wall formed. The thickness of a wall has to be identified by considering the principal balance between the wall’s geometry. A good example would be to assess how possible it is to have a strong plastic wall. Usually, the thickness of a wall tends to exert an impact on the production cost. With the application of plastic molding, these costs can slightly be lowered.

- Plastic Molding Enhances Durability In Products

Thicker plastic walls are known for their strength and ability to withstand pressure. On the other hand, thinner plastic walls are known for their weakness. With plastic molding, the idea is to keep the inner part thicker and lighter, especially when production runs slightly longer. By maintaining thin walls, you’ll realize that you can enjoy a greater warping resistance.

- Gas-Assisted Plastic Injection Molding

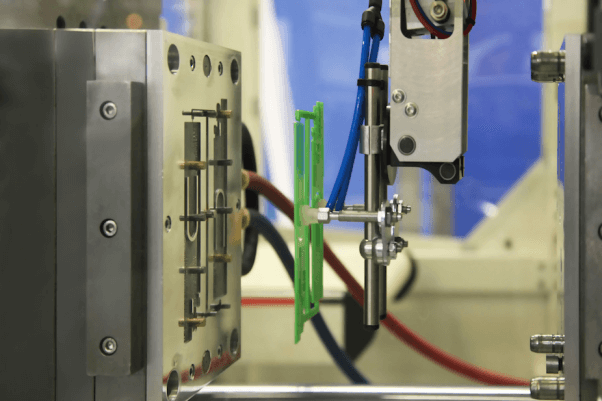

Gas-assisted plastic injection molding is a standard method of production used in creating plastic products. Usually, the gas will generate a bubble that will push the plastic to the end of the mold. Since there are different types of molding used in the plastic manufacturing sector, this is one of the best. It’s majorly applied in a casting polymer.

- Bras Plastic Injection Molding

Plastic injection molding has different capabilities intended to help professionals in the automotive sector to handle their projects successfully. In many cases, it’s used in upgrading products as well as processes. Other additional applications are such as formulation development and development of molds in the manufacturing sector.

- How Plastic Molding Is Used In The Automotive Sector

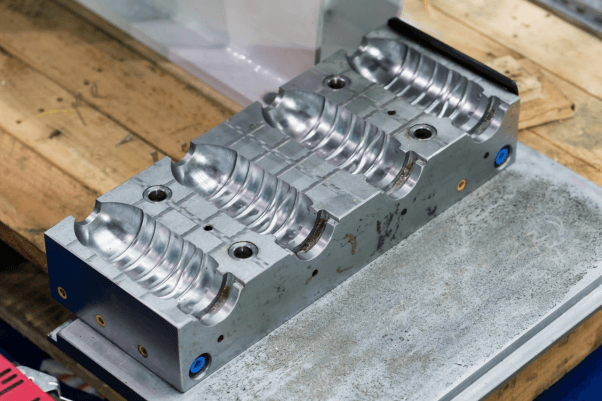

In the automotive sector, plastic injection molding automotive is used to enhance production. Towards that end, injection molding relies on the robust metallic metal molds. Other than that, the plastic parts that have been produced after the utilization of mold will practically be identical. On the other hand, if the mold has well been designed, then injection molding becomes a repeatable process.

Take-Home

There are several benefits of using plastic injection molding. There are also advantages to using this manufacturing process. As a business owner in the production sector, you need to be familiar with all these processes. That’s why it’s essential to analyze significant applications of plastic molding, as highlighted in this article.