A complete guide of the process of making beer

Beer is an alcoholic drink that is manufactured by brewing and fermenting of cereals. Typically, beer is made from malted barley and flavored hops. The fact that these products have a slightly bitter taste makes them the perfect raw material for beer. Maize, barley, and rice can also be used as a raw material. In addition to the cereal, beer is also made using water and yeast. The brewing of beer is something that can be done at home as well as in large establishments and factories. Deruna beer equipment manufactures machines that are used in the process of manufacturing beer. In this post, we discuss the process through which beer is made.

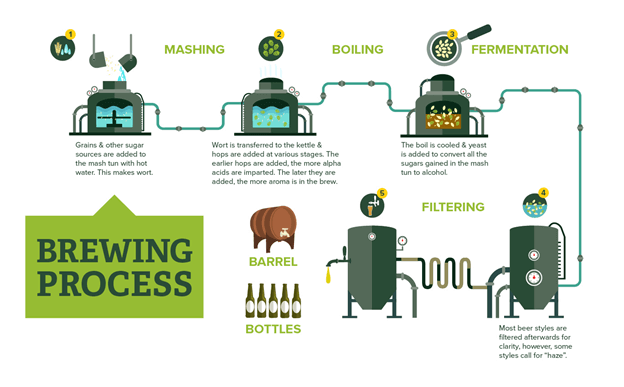

The process of making beer

- Malting- this is the first step of the process. Malting is the process through which grains are transformed from their harvested form into a cracked form. The grains first have to be collected from the firm then processed through heating. The heat helps to dry them out and break them. The role of malting is to isolate specific enzymes found in the grains that are needed for the brewing process.

- Mashing- this step is almost similar to making tea. This means that cracked grains are steeped in hot water. Keep in mind that the water is not boiling. This action helps to activate the enzymes in the cracked grains. The activation of these enzymes causes the grain to breakdown hence releasing its sugars. The water used in the process collects the released sugar and is drained from the grains. At this point, the sweet, yet stocky liquid is referred to as the wort. The wort is used to make the beer like dough is used to make bread.

- The next step involves the boiling of the collected wort. The boiling process lasts an hour. As the wort continues to boil, spikes and hops are added into it on several occasions. Hops help to create a balance between the sweet taste of the wort and bitterness while also acting as a preservative.

- Once the hour has come to pass, the wort is removed from the boiler and cooling. Once it is cooled, it is also strained and filtered.

- The next step is to pass the strained and filtered wort through fermenting vessels. In these vessels, yeast (responsible for fermenting) is added to the wort. This marks the end of the brewing process and the start of the fermentation process.

- In the presence of yeast, the brewed beer is stored for not less than a couple of weeks. The storage of the beer is done at room temperature. If it is during the cold season, it lasts for longer than a couple of weeks. Once the fermentation process is complete, you have successfully manufactured beer and can now embark on the bottling process.

Bottom Line

After fermentation, although the brewing process is typically completed, the product cannot be consumed at this time. It still has to go through a maturation stage that allows it to develop its flavors fully. As it matures, the yeast continues to release carbon dioxide in a process that causes the beer to be carbonated. Keep in mind that this last process happens after the beer has been bottled already.