The Material Flow During Metal Extrusion Processes

In the current scenario, extrusion is a term used to refer to a variety of semi-moist materials. These elements have varying moisture forced through a barrel temperature, screw, and configuration into a cross-section die opening.

The metal extrusion process is a predominant mechanical processing operation in several industries. It combines various unit operations such as coating, mixing, and shearing, among others. The success of these projects depends on the material you choose to use.

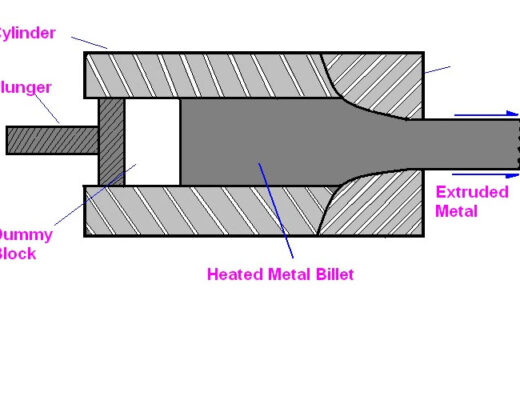

The origins of the extrusion are usually in the metallurgical sector. Secondly, having been patented to improve machining designs, continuity, and sustainability is considered a great impeccable thing to do because of extensive research. To understand the extrusion process, take a look at the extrusion diagram below.

The outset of metal extrusion and barrels

It all started when experts developed sausage extruders in the 19th century. It was a simple machine. After that, several developments laid a foundation for the food extrusion business. A pasta extruder was referred to as a cold extruder.

The general mills were developed in the 1930s. Twin-screw extruders were also developed at that moment. Later on, experts in the manufacturing industry developed pet food extruders. Adapted from the polymer sector, the rise in food quality coupled with the screw extruders’ limitations became an improved version of the original ones.

In the years that followed, several changes were notable in the design of extruders. Some of these changes included screw design and barrel design. The material used to bring out these designs was also considered in several cases.

Withstanding heavy metallic pressure

The barrel liners with segmented screws would also add economics to these processes. The processes would increase a lifetime in the long run. For enhanced wearing characteristics, several screw elements from various materials were used. Standard nitride steel was also used to develop extruders.

Similarly, various options for metallurgy are readily available for manufacturers. These elements can withstand higher temperatures and internal pressures. The barrels lined with robust cobalt-based alloys give abrasion coupled with chemical resistance to the metals.

Basic extrusion processes

Metal extrusion processes involve a large combination of various transportation processes, such as a flow of materials in a controlled environment system. At the same time, it encompasses thermal energy transfer within the materials involved. Over and above, metal extrusion processes have an extruder too.

Puffing of the metal extruders can cause the release of gas during the process of expansion. That way, it becomes easy to form an expanded foam and structure. This is an energy input to the process of extrusion. Then, there is the transfer of screws from heaters using a barrel well.

The result is thermal energy from sources that can increase the temperatures of the said materials being extruded.

Final Thoughts

The desirable force for extrusion, especially in direct extrusion, often varies with the RAM travel. Before anything else, the billet will be compressed. It should take the container’s size prior to extrusion. Additionally, before that, the friction between the billet as well as the container begins to reduce. The highest pressure is often at a point where extrusion begins- the breakthrough pressure.