CNC machining vs. rapid prototyping

Both CNC machining services and rapid prototyping have experienced a lot of advancements in the past few years. Not only have they become more effective, but they’ve also become more efficient. Many operators will have their respective opinions about which one of these technological tools works better for them. Most of the time, it is based on preferences.

In this article, these two technologies will be compared and contrasted; what they offer, and how they can better the life of operators or make it worse. Let’s take a look at what makes one of the products better than the other and why you might want to choose one over the other.

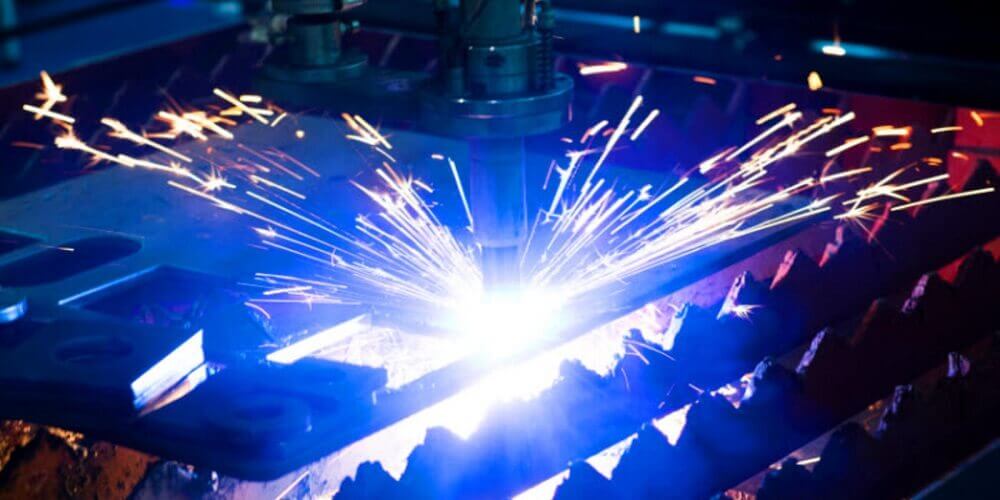

CNC machining

When it comes to milling any kind of material that you can think about efficiently, the first thought that hits you is usually CNC machining centers. Any material you can imagine can be milled on the machine.

The system allows you to fabricate and mold any kind of part with ease no matter how large or how small. To make the process easier for much larger parts, it would only take more machining tools and nothing more.

When it comes to the complexity of each part, CNC machining tackles every feature in the part, making it a bit more time and cost-consuming. CNC is at its fastest when the parts are simple and straightforward. They’re twice as fast as rapid prototyping and can make the job much easier and satisfying. However, when you have to work on complex parts CNC is much slower compared to its counterpart.

CNC can become even more expensive when it comes to deep slots and holes, square corners, and high aspect ratio features. If what you’re looking for is perfect detailing, CNC is the way to go. You’re offered sharp edges, smooth chamfers, and smooth blends.

Rapid prototyping

Having looked at what CNC machining is and the advantages/disadvantages, let’s go ahead and look at that if rapid prototyping.

Unlike CNC machining that can work on any kind of material, there’s still a limited number of materials that rapid prototyping can work on. It cannot process a part size higher than 24 x 36 x 20 m. This doesn’t take away RP’s advantage of producing complex parts with speed and at fewer costs. Although CNC produces a very massive range of materials, there can be situations where rapid prototyping can produce some features that CNC cannot.

RP brings lead time to the nearest minimum not minding how complicated or complex the material is. It doesn’t require too many steps to produce features, neither does it require the extra labor that CNC machining services need.

Conclusion

You can’t take away the fact that both technologies offer awesome benefits to the operator depending on the expected result. Note that you read at the beginning of the article that it’s totally based on preferences as any of the equipment can serve the purpose you want.

At the end of the day, it’s still your choice at the day. So make the right call.