What is DLP 3D printing, and how does it work?

VAT polymerization is a term used in 3D printing technology. It refers to a form of technology that uses liquid polymer resins under ultraviolet light to construct a model layer after another. The role of the UV light is to harden the liquid polymer resin where necessary. In the process, the object moves on a platform allowing one layer after another to be hardened. VAT polymerization is used explicitly in DLP 3D printing. DLP (digital light processing) 3D printing uses VAT polymerization technology in the production of 3D objects. There are different types of DLP 3D printers in the market, including LCD Resin 3D Printer.

How do DLP 3D printers work?

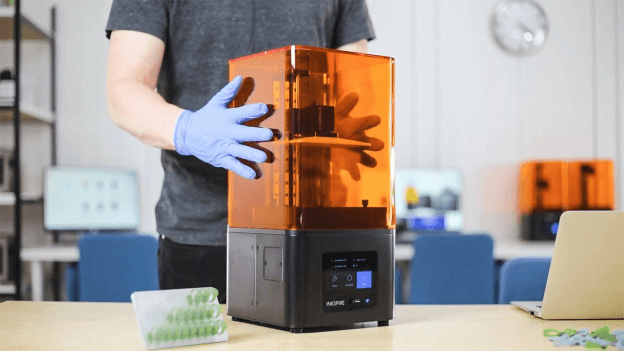

DLP 3D printing technology is in many ways similar to SLA technology. SLA (Stereolithography) 3D printing technology works by hardening the liquid resin layer by layer using light. The process is called photo-polymerization. On the other hand, DLP also uses light to harden the resin. DLP 3D printing also uses projectors under the tank of resin to expose an entire layer at once. SLA 3D printing and DLP 3D printing modes of 3D printing are the most common modes of resin 3D printing in the market.

The first step to DLP 3D printing is importing or feeding the 3D model into a slicing program. The slicing program translates the dimensions and other features of the model into a language that the 3D printer can understand. The next step would be to fill the filler tank with liquid polymer resin. A build platform is then lowered into the container as one of the layers of the object being designed is traced using a UV laser. The UV laser is positioned using a galvanometer. The galvanometer is a set of mirrors that reflect the laser through the rotation.

The ultraviolet light allows the liquid resin to harden into a solid hence creating the layers of the object. This process is repeated until each layer is produced and later combined.

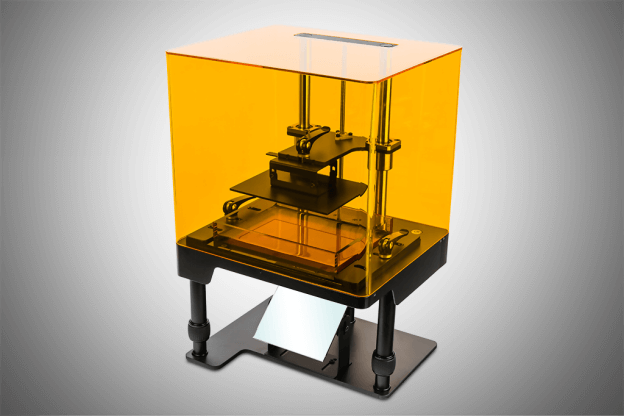

The LCD Resin 3D Printer

The LCD Resin 3D printer is a type of DLP 3D printer. The following features make this type of printer stand out from the rest in the market:

- It features a 2K screen with final prints that allow for the production of fine textures

- It features a 0.02-0.05 MM precision

- It also comes with an anti-aliasing feature of up to 4X by 8X

- It features uniform light that allows for an accurate precision with a 90 percent light evenness feature and a 30 percent higher accuracy than others in the market

- It has detailed processing features that reduce the issue of jagged edges

- It is also very accurate

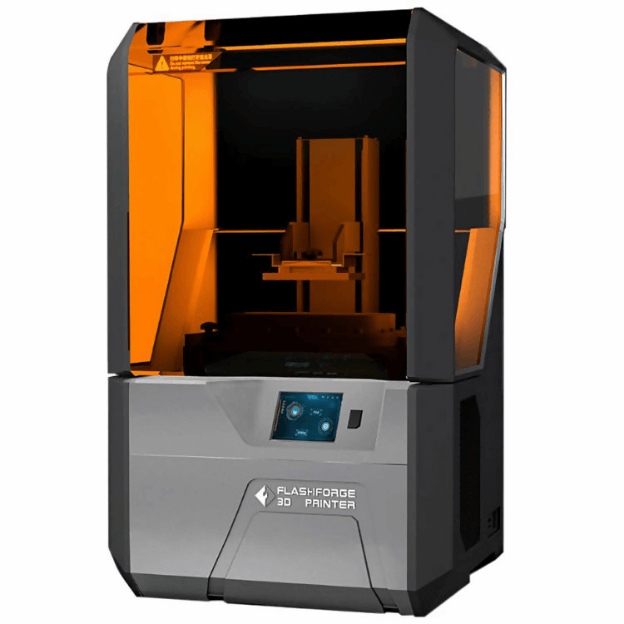

Resin 3D printers

These are some of the most common modes of 3D printing as they are highly accurate, isotropic, and allow for the production of quality objects.

Bottom Line

Between SLA and DLP 3D printing technologies, DLP is the cheaper one hence the most accessible to the average user. Other than the cost, other differences between the two technologies lie in the areas of accuracy, strength, and efficiency.