Process of Manufacturing

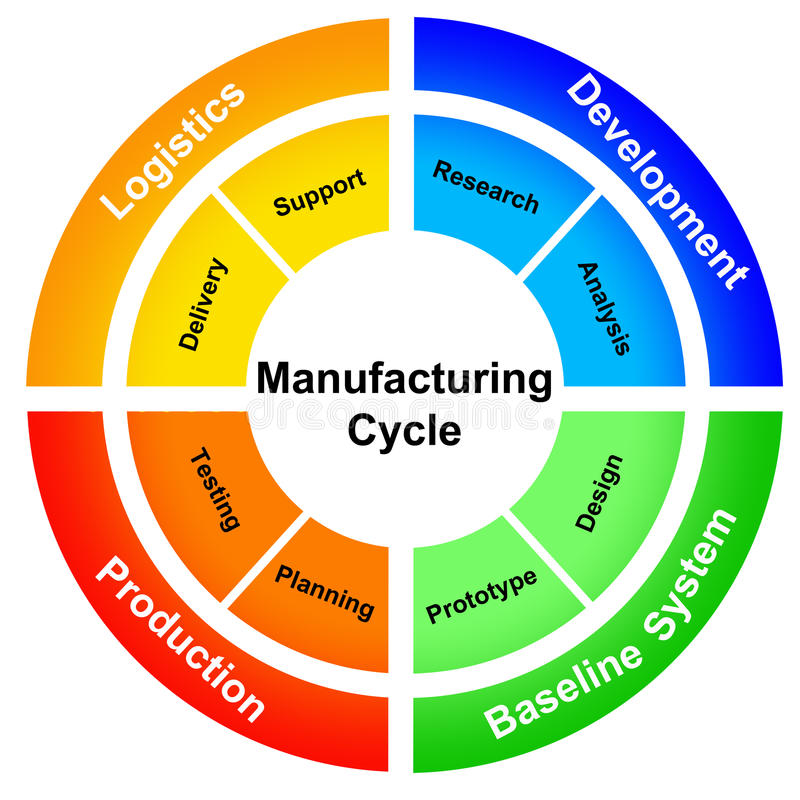

Manufacturing Engineering is a branch of professional engineering concerned with the understanding and application of Engineering Procedures in Manufacturing Processes and Production Methods. The meaning of Manufacturing is the business of making things in factories.

Manufacturing Engineers:

It doesn’t end there. Manufacturing Engineers also get involved in supply chain management, logistics and distribution, quality management as well as environmental and life-cycle management.

In short, Manufacturing Engineering is the branch of engineering that is concerned with understanding, analyzing and improving complex industrial, manufacturing and infrastructure systems.

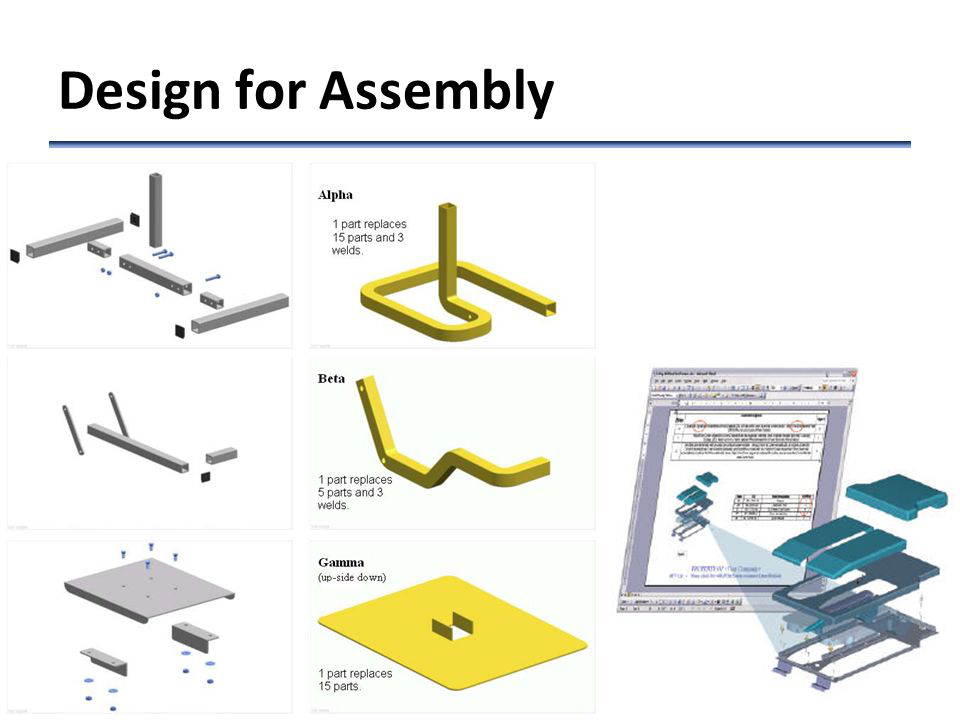

Design for Manufacturing:

DFM is the method of design for ease of manufacturing of the collection of parts that will form the product after assembly.

DFA is a tool used to select the most cost effective material and process to be used in the production in the early stages of product design.

Design for Assembly:

DFA is a process that requires involvement of Assembly Engineers.

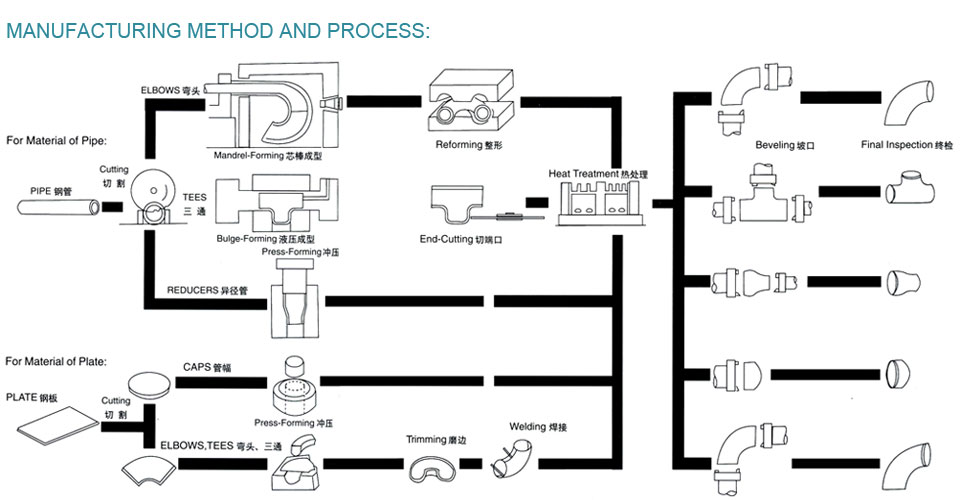

Manufacturing Method:

Manufacturing Engineering is based on core mechanical engineering skills, adding important elements from mechatronics, commerce, economics and business management. Why? Think about it like this. Say a factory needs designing. Not only does the factory need to produce a product, it also needs to produce it efficiently and be able to meet the demand for the product, and do so at the right cost, quality and delivery timeframe.

Phew, sounds complicated. And it can be. But because Manufacturing Engineers can see the ‘big picture’ as well as ‘the specific details’, their training, and broad skill set make it easy for them to get the job done. Manufacturing Engineering is probably the most flexible and marketable of all the engineering disciplines. In fact, many engineers that originally studied other engineering disciplines will end up practicing as Manufacturing Engineers.

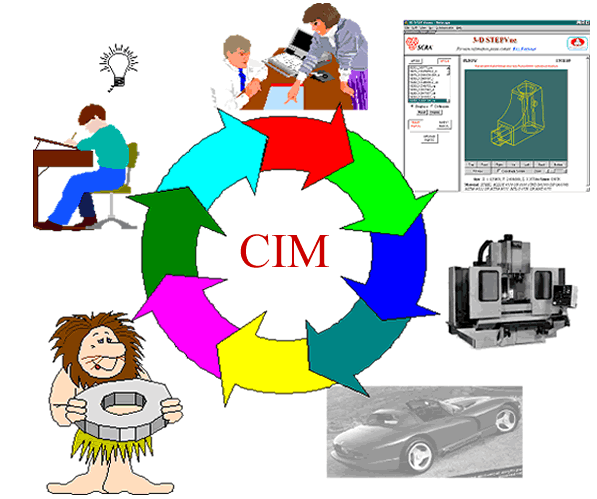

Computer-Integrated Manufacturing (CIM):

Computer-integrated manufacturing (CIM) refers to the use of computer-controlled machineries and automation systems in manufacturing products.

CIM combines various technologies like computer-aided design (CAD) and computer-aided manufacturing (CAM) to provide an error-free manufacturing process that reduces manual labor and automates repetitive tasks.

The CIM approach increases the speed of the manufacturing process and uses real-time sensors and closed-loop control processes to automate the manufacturing process.

It is widely used in the automotive, aviation, space and ship-building industries. CIM is a manufacturing approach that provides a complete automation of a manufacturing facility. All the operations are controlled by computers and have a common storage and distribution. CIM systems require higher degrees of data accuracy to run properly.

Once part, bill of material, inventory and operational information achieve a very high level of accuracy, CIM can perform functions with minimal human intervention and then report on the results automatically.

Humans are still required to monitor systems, but elimination of human error in many assignment and reporting functions on factory floor operations drastically reduces the error rate.

Assignment and reporting in a CIM environment are performed automatically and immediately without any delay involved with people-based transactions. Depending on the environment, this additional speed allows operations to be performed as soon as previous work occurs without any lag time.

CIM environments therefore reduce the time it takes to perform manufacturing fabrication and assembly, allowing quicker flow of product to customers and increased capacity.

Once operations are assigned and reported in a CIM system, changes to various operations can also be performed more easily. CIM systems are designed to be entirely paperless, eliminating the barriers to changing operations.

This flexibility, combined with the speed it can be performed, allows companies to quickly react to market conditions and then return to previous settings when market conditions change.

Factory floor operations are not integrated in non-CIM situations; manufacturing operations and material usage must be reported by humans who perform transactions. CIM offers a degree of integration that enables the flexibility, speed and error reduction required to compete and lead markets.

Integrating factory floor operations with enterprise software enables employees to do higher value functions for their companies.

Manufacturing Engineering is the activity of carrying out the production of the product, involving further enrichment of the database with performance data and information about the production equipment and processes.

In CIM, this requires activities like CNC programming, simulation and computer aided scheduling of the production activity. This should include online dynamic scheduling and control based on the real time performance of the equipment and processes to assure continuous production activity.

Often, the need to meet fluctuating market demand requires the manufacturing system flexible and agile.

Factory automation equipment further enriches the database with equipment and process data, resident either in the operator or the equipment to carry out the production process.

In CIM system this consists of computer controlled process machinery such as CNC machine tools, flexible manufacturing systems (FMS), Computer controlled robots, material handling systems, computer controlled assembly systems, flexibly automated inspection systems and so on.

Products are designed, produced and delivered to customer specifications in response to an order. Examples are custom-tailored clothes, custom-built homes, and component parts for a machine, a PCB for a school-based project.

The important issues here are to meet the needs of the customer and to complete the order in the minimum amount of time

Manufacturing enterprises can range from very small companies having just a few people to very large multinational companies who employ thousands.

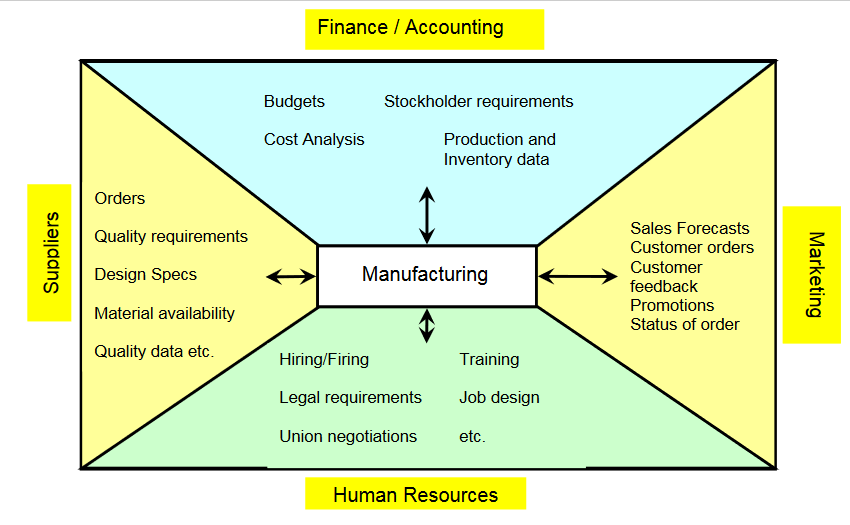

Apart from the very small companies, a modern manufacturing enterprise usually has a structure like that shown below. It can be seen that manufacturing is just one part of a complex process that represents the company as a whole.

In the above diagram, the arrows show how the various components of a manufacturing enterprise interact with one another. The four segments describe what type of information is exchanged between itself and the manufacturing department.

The type of information determines which direction it flows. For example, Marketing will provide customer orders to manufacturing. On the other hand the status of the order at any given time will be sent from manufacturing to marketing.

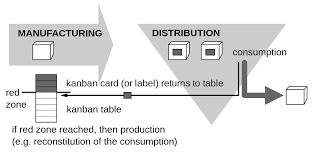

Manufacturing Kanban Systems:

Kanban is the Japanese word for card. Kanbans are used in JIT as part of a ‘pull’ system that is used to regulate flow of the materials and component parts through the manufacturing system.

A major problem in assembling a complex item is the coordination of the parts and sub-assemblies as they move along the production line. With a car, these amount to dozens of sub-assemblies consisting of thousands of components.