Working Principle of Thermowell in Temperature Measurement

A thermowell is defined as a pressure-tight receptacle device that is constructed to accept a temperature sensing constituent. It offers a way to introduce that constituent into a vessel or pipe.

According to the American Society for Testing and Materials (ASTM), thermowell is a closed-end reentrant tube that is particularly constructed for the introduction of a temperature-sensing constituent. It is provided with means for a pressure-tight connection to a vessel.

Construction

Thermo wells are designed to guard the temperature measurement tool from:

- Chemical attacks

- Forces because of the fluid flow

- The pressure effects

Shanghai Wan Hui Machinery Co., Ltd is providing you with a huge range of mechanical products, including thermowell, orifice fitting, flowmeter, flow conditioners, and many more. All the products are manufactured according to safety standards. Your customized designs are also accepted by the company. Check the official website of the company and place your order now.

To achieve this functionality, thermo wells are constructed from a variety of durable materials such as:

Teflon Thermowell

It is made from Teflon material. It is employed when procedure temperature and pressure are from low to moderate.

Stainless Steel Thermowell

It is utilized when the process fluid is greatly corrosive.

Ceramic Thermowell

It is utilized when the temperature is elevated. Ceramic inserted in silicon carbide thermowell is employed when the temperature is high, and pressure disparity is small.

Chromium/Molybdenum Steel Thermowell

It is utilized in extremely pressurized applications.

Alloyed Thermowell

This thermowell is a mixture of nickel, cobalt, chromium, and tungsten. These thermo wells are employed when the procedure stream consists of sulfur, carbon, or chlorine.

Working Principle of Thermowell

Thermo wells offer defense for temperature probes against adverse operating situations like:

- Corrosive media

- Physical impact (e.g., Clinker in furnaces)

- High-pressure gas or liquid

Their consumption also allows fast and simple probe interchanging without the requirement to open up the procedure. Thermo wells are, in general, made of solid drilled-out bar stock. These are manufactured to defend temperature sensors from flow, elevated pressure, and harsh surroundings.

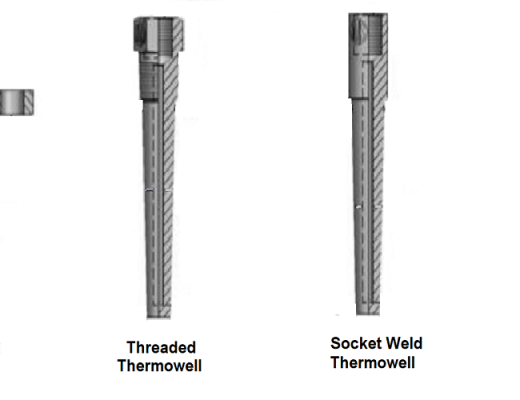

Thermowell’s Installation

The installation of thermowells is very important for its proper working. The connection/installation is totally dependent on the process. There are three possible positions that you can use while installing a thermowell in storage vessels or pipes, but installation has no specific directional restrictions.

One thing that you should guarantee is the self-draining of the system. Any opening to identify the leaks should be at the lowest possible position.

The accuracy of this equipment is greatly affected by the immersion length. Very small immersion length can cause measurement error during the heat conduction through the container walls or other connections.

To determine the ideal immersion length, you need to consider many other factors like process pressure & flow velocity. Other than immersion length, you need to consider various factors while installation that includes: flow type, process media, tank/pipe size, and two-phase flow.

Why Utilize a Thermowell?

If the measurement is not significant either to the protection of the plant or to the effectiveness of the construction, and if the procedure fluid is not chiefly violent or hazardous, it might be probable to introduce a sheathed, stainless steel industrial thermometer into the plant pipeline via an appropriate solidity fitting.

The thermometer could not be detached while the plant is operating, and must a difficulty occur with the measurement, upholding will be deferred until the procedure can be stopped and the line drained and made secure.

Conclusion

If you want to install temperature measuring devices in the pipes in a hidden way, then you can do it by using a thermowell. You must select a thermo well made from such material suited for your application.